Services

From printed circuit board design to shipping the finished PCBA, we work closely with you and involve you in the individual project steps. Our efficient project management enables us to process your order quickly and reliably.

Individual advice on cost savings

In-house

production facilities

Fast

quotation generation

Industrialization

with efficient

3-shift production

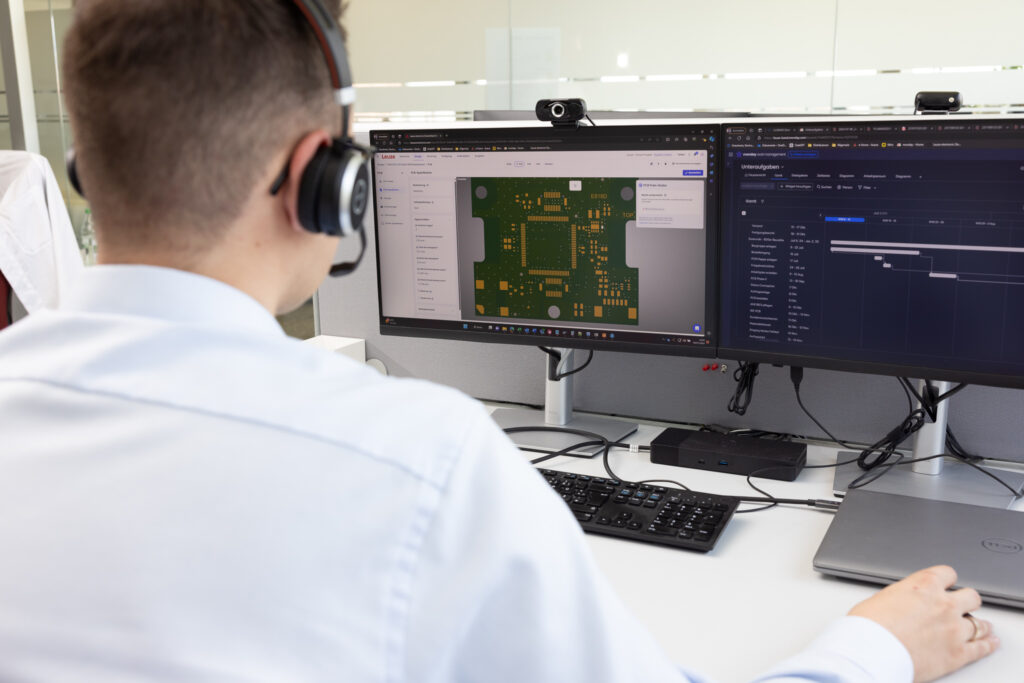

Transparent

project management

Customized

packaging and delivery

Technologies

As a technology leader in electronics production, we work with the latest technologies on the market. We can respond flexibly to your requirements and offer you cost-effective solutions.

Programming

- Fully automatic component programming

- Software can be flexibly adapted until shortly before the start of production

- Cost-effective terms and conditions

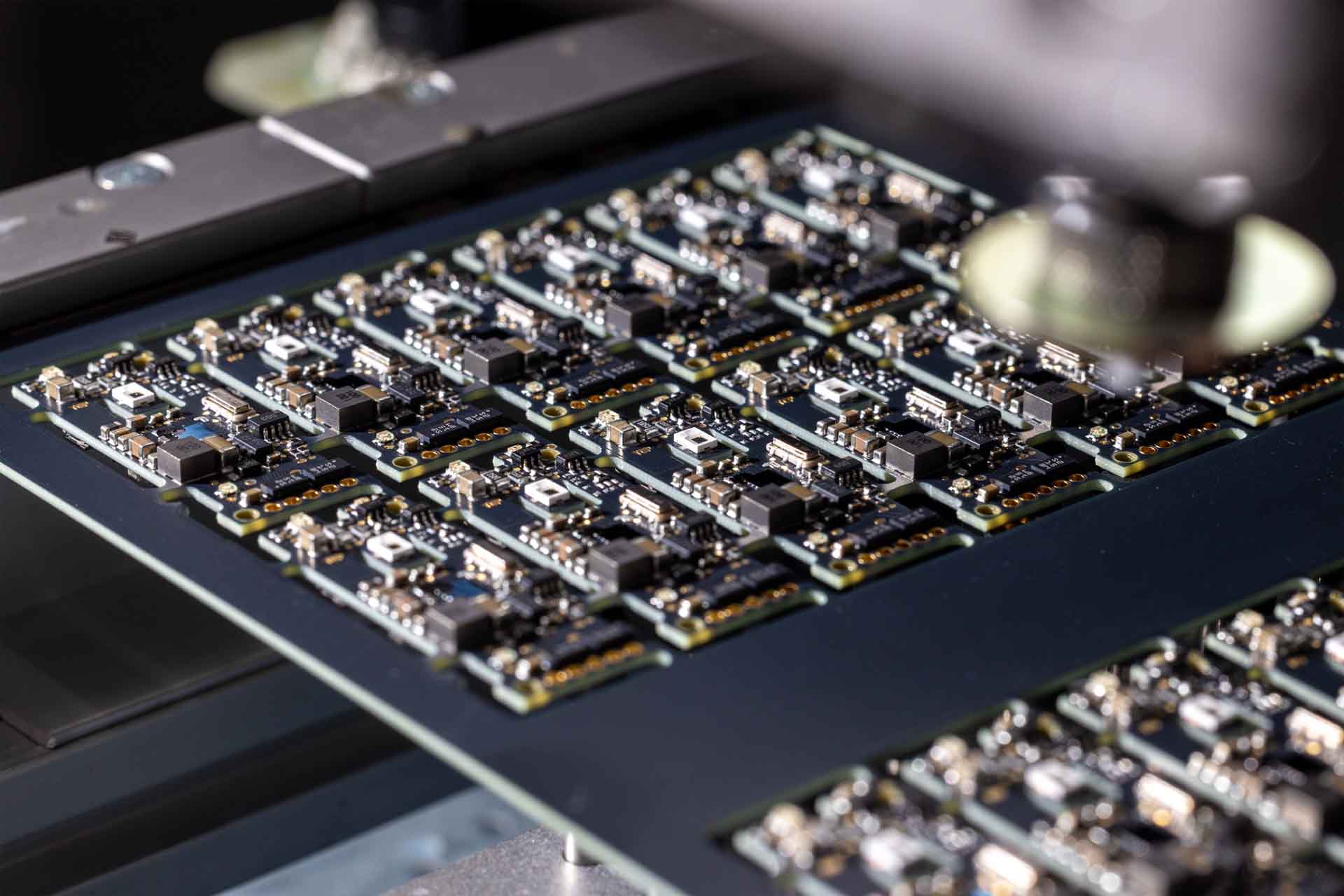

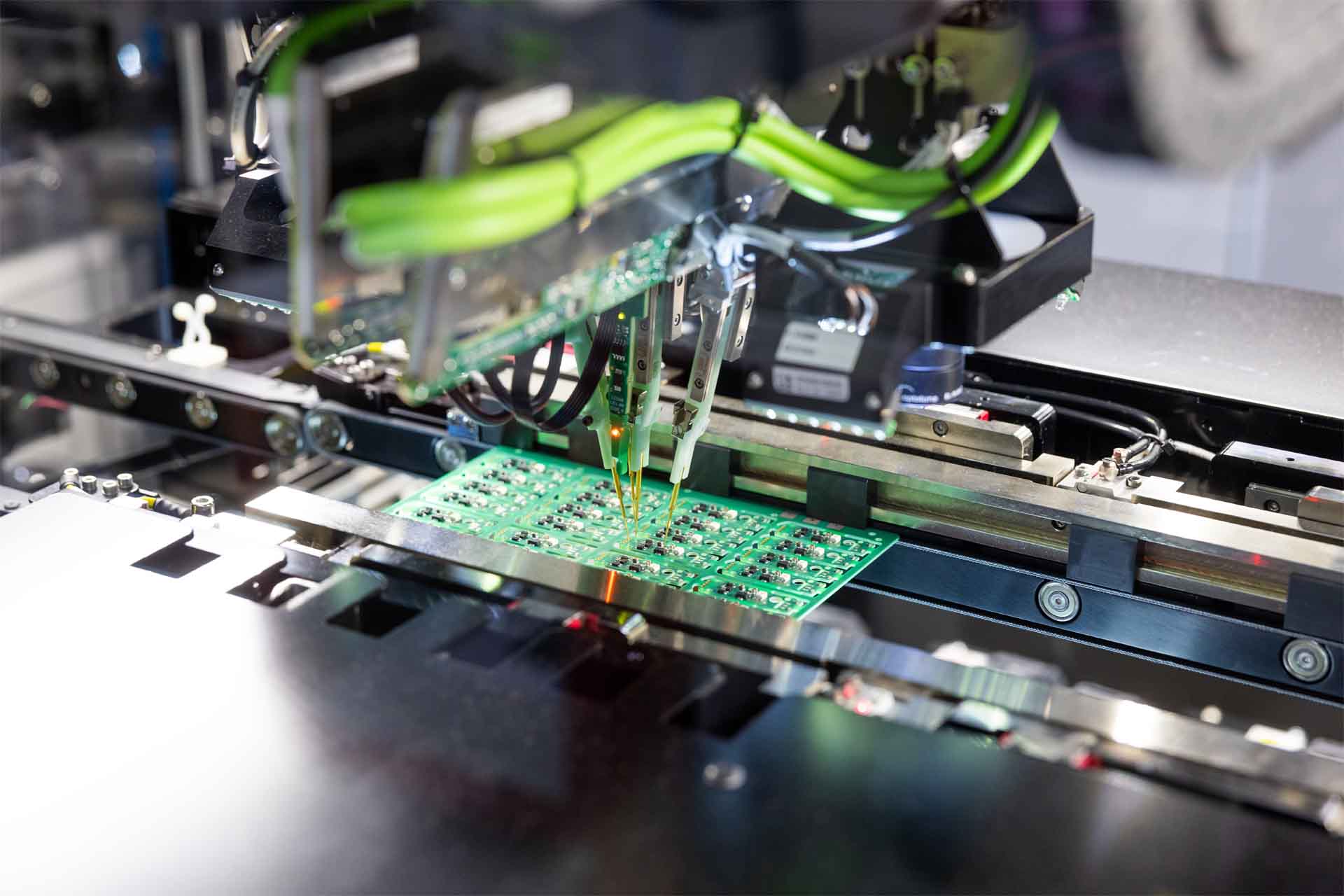

SMD-Process

- Solder paste printing with SPI

- System type: FUJI NXT3 P&P real up to 100,000 CPH

- Soldering under controlled inert gas atmosphere

- Automatic 3D inline optical inspection

Micro-Assembly

- Components, diaphragms & COB technology

- Placement accuracy: +/- 15 µm

- Mechanical bonding with inline UV curing system

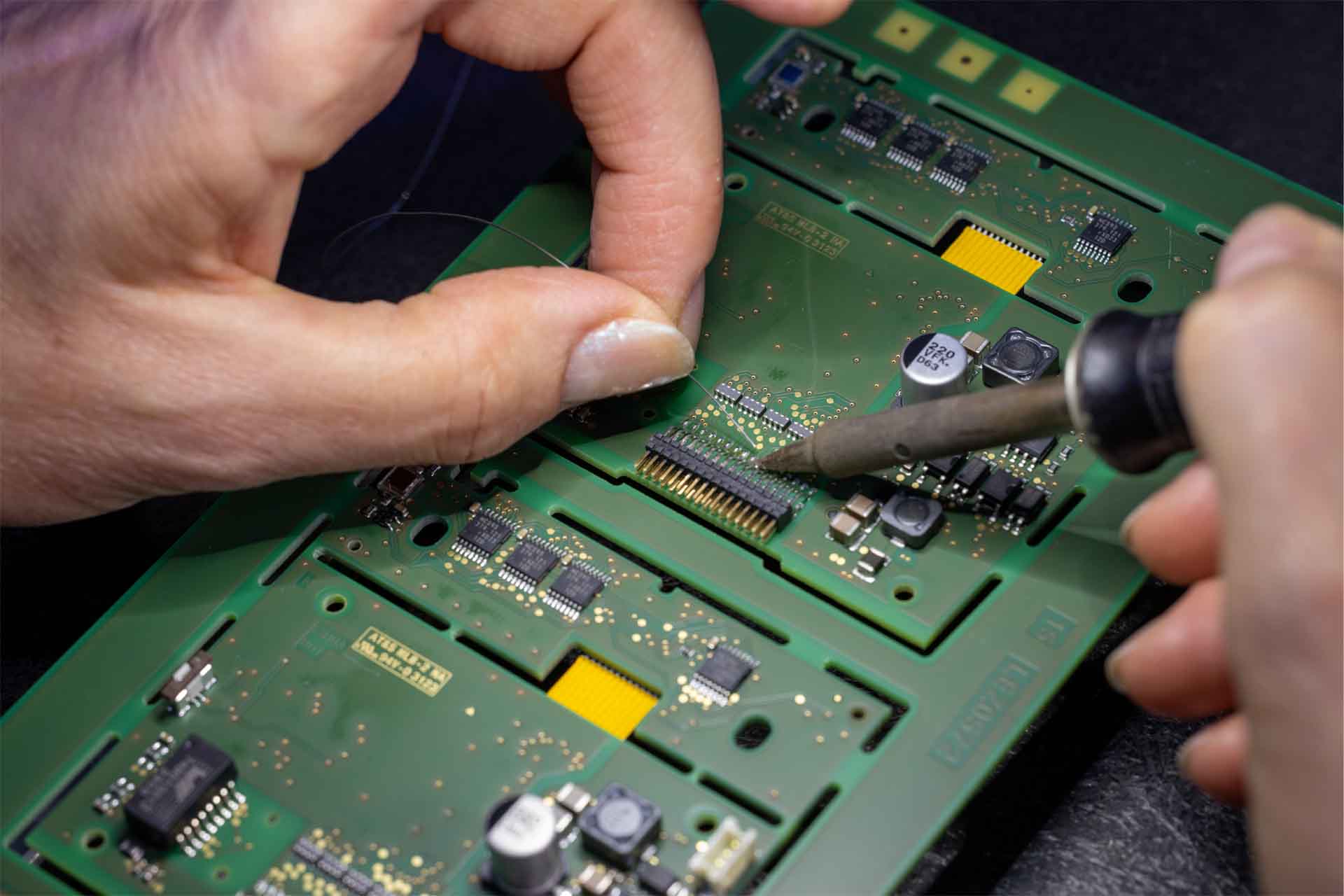

THT Soldering

- Hand soldering

- Wave soldering

- Robotic soldering

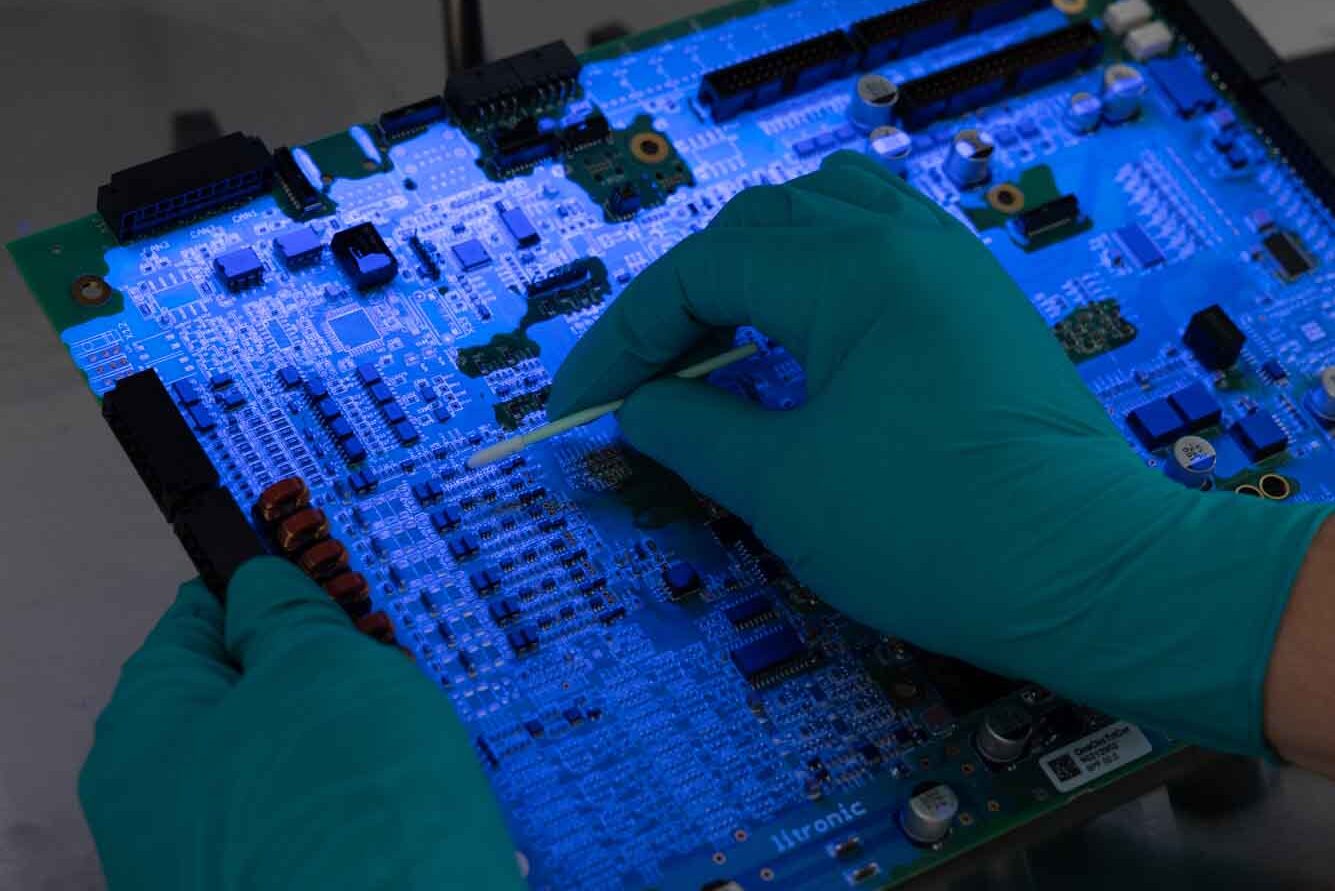

Coating

- Protective coating and sealing of assemblies against moisture and extreme external influences

Electrical Testing

- In-circuit testing: flying probe

- In-circuit testing: inline bed of nails

- Inline functional test

- Customized functional test

Depaneling

- Circular blades

- Double linear blades

- Milling

- Laser cutting

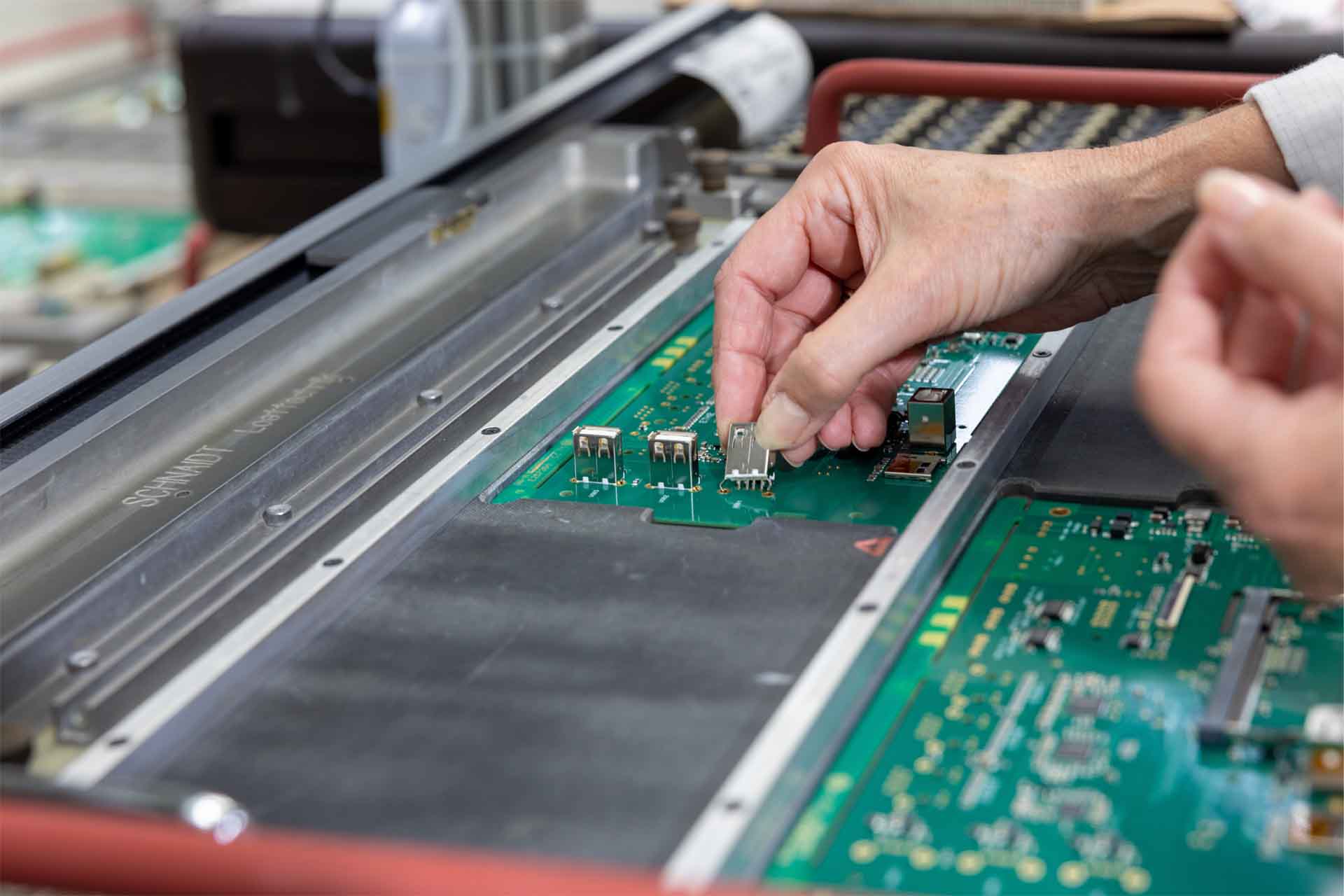

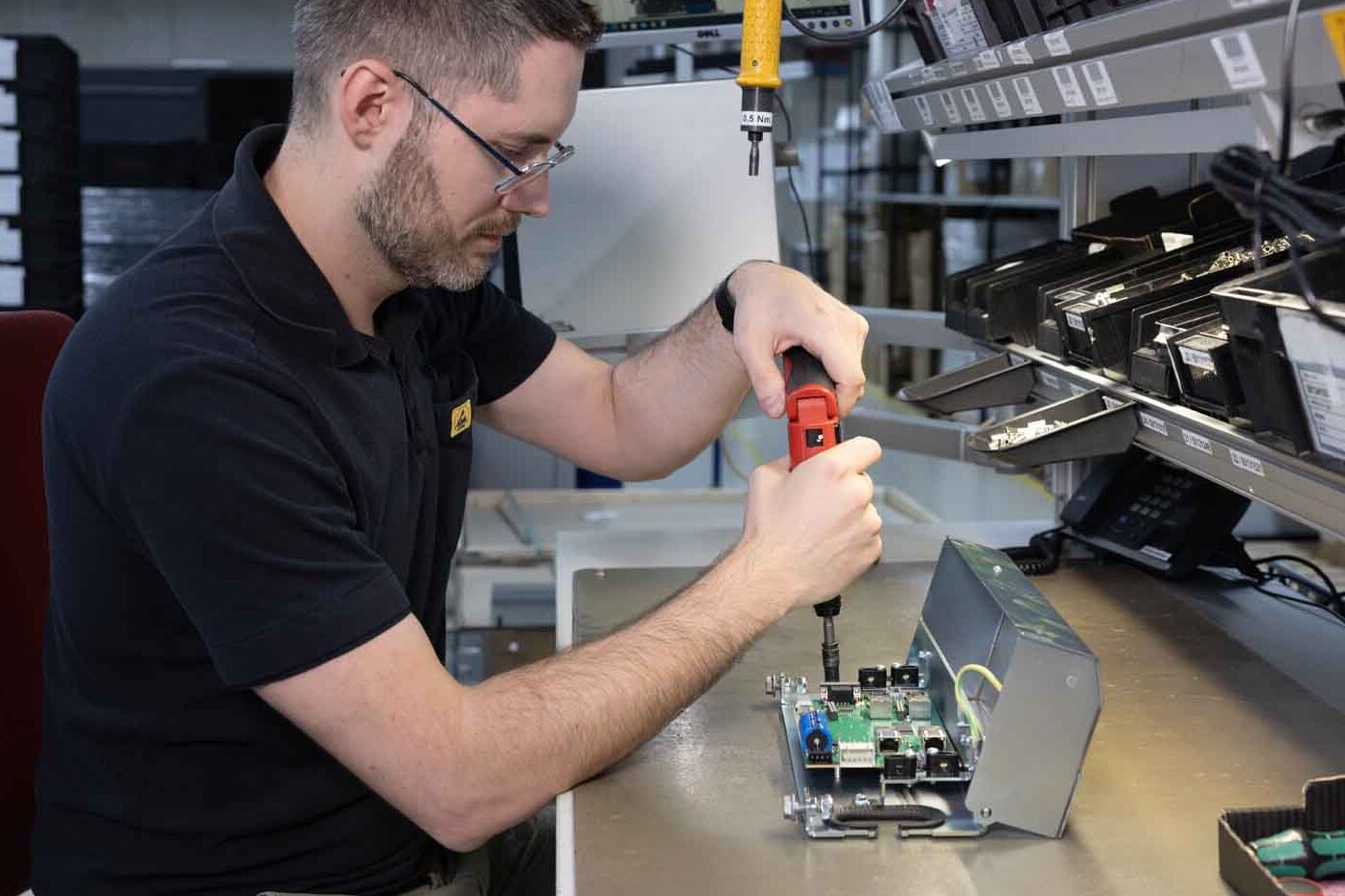

Module Assembly

- Integration of the circuit board into a module (on customer request)

- Bespoke packaging, labeling and delivery